LubeLogic Chain Lubricators

Chain lubricators provide conveyor chains with the oil to keep machinery lubricated and running smoothly. Lube Logic chain lubricators provide your conveyor chain with accurate and reliable lubrication which leads to a more efficient and effective production process. All our lubricators feature speed compensation logic which utilizes built in sensors that sense where the chain is in order to accurately dispense on the right part of the chain every time, reducing wasted material and mess.

These systems are self-contained, requiring only lubricant, compressed air, and electricity. Lube Logic systems come standard with a two-gallon steel reservoir, a low-level float switch, a low level indicator light, and a microprocessor with a programmable count controller. They are capable of operating in either conveyor travel direction, meaning they can be installed with the “front” on either side of the conveyor. Lube Logic Chain Lubricators lead to reduced downtime and less manual labor in the chain lubrication process. The standard tank size of our lubricators is 2 gallons, though we have an impressive variety of configurable options to craft a system for your precise lubrication needs.

GP Reeves offers a complete line of Lube Logic Conveyor Chain Oil that is compatible with a wide range of manufacturing environments and is engineered to optimize chain performance and extend the lifespan of your system.

Why GP Reeves Chain Lubricators?

Chain lubricators were the first product featured in the GP Reeves portfolio. For over 50 years, we’ve been developing and innovating our chain lubricators to ensure they provide the best conveyor lubrication solution possible. We’ve served a variety of industries all over the world with our chain lubricating technology and are always looking for opportunities to increase efficiency and effectiveness with more chain lubricator projects. GP Reeves also has the ability to customize our chain lubricators, so you can be assured that even your most unique chain lubricating needs will be satisfied!

Features and Benefits

-

-

- Lubricators can dispense oil with viscosities from ISO 2 to ISO 100.

- Systems can repeatedly lubricate up to 80 ft of chain per minute.

- Airless shot nozzles include a check valve to prevent unwanted material bleeding.

- Positive displacement dispensing guarantees the same amount of oil is dispensed every time, regardless of temperature and viscosity changes in the facility.

-

Our Chain Lubricators in Action

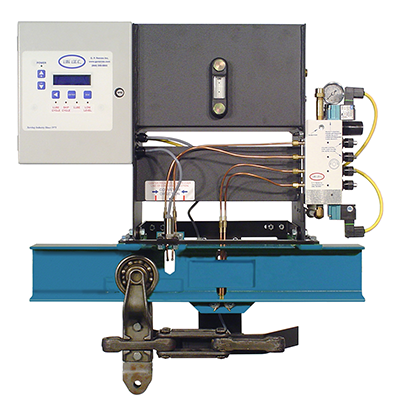

Our advanced chain lubricator systems have been supporting industries around the world for decades. To the right, we have one of our chain lubrication models in action. This advanced system provides reliable lubrication and can be depended on for years.

Chain Lubricator Selection Guide

When selecting an oil lubrication system, it is important to evaluate the type of conveyor system the oil will be dispensed to. The shape of the conveyor tube is the most important aspect. We offer lubricators for “I” beam, square and round enclosed tracks, as well as inverted enclosed tracks, though custom solutions are always a possibility. It is worthwhile to note any unique components of your conveyor system, as there are specific oil lubricators that take into consideration aspects such as chain length, wheel size, overall width, and wear points.

I-Beam Style Lubricators

These lubricators are designed to lubricate I-Beam conveyors. Two models are available, the SS3000 lubricates just the chain pins, whereas the SS5000 lubricates both the open trolleys and the chain pins.

SS6000

SS6000 lubricators are designed for use on standard enclosed track conveyor chains.

SS6100

SS6100 lubricators are for 8” pitch square enclosed track conveyors with plastic and steel wheels and randomly spaced 4-wheel trolleys.

SS6300

SS6300 lubricators are designed for inverted square enclosed tracks, where the opening is on the top of the conveyor rather than the bottom.

Custom Lubricators

If none of our standard options meet your needs, don’t worry! We offer unlimited possibilities and customizations when engineering a fully custom lubricator for you.

Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service