PRODUCTION DISPENSING FOR THE AUTOMOTIVE INDUSTRY

GP Reeves is a leading expert in dispensing equipment for the automotive industry. We have created custom solutions for a vast array of businesses within the automotive sector, including OEMs, and are constantly adapting to the new innovations and needs of the industry. We have worked with names like Ford, GM, Jeep, Tesla, and more!

How We’ve Advanced the Automotive Industry

GP Reeves has gained a wealth of expertise in combining modern engineering with custom design. We’ve provided countless solutions for the biggest challenges of the automotive field, and our customers have gained several advantages from partnerships with GP Reeves. GP Reeves automotive dispensing machinery enables you to:Decrease Downtime

Increase Cost-Effectiveness

Elevate Production Capacity

Reduce Wasted Material

Enhance Product Quality

Improve Efficiency

Increase Worker Safety

Enhance Profitability

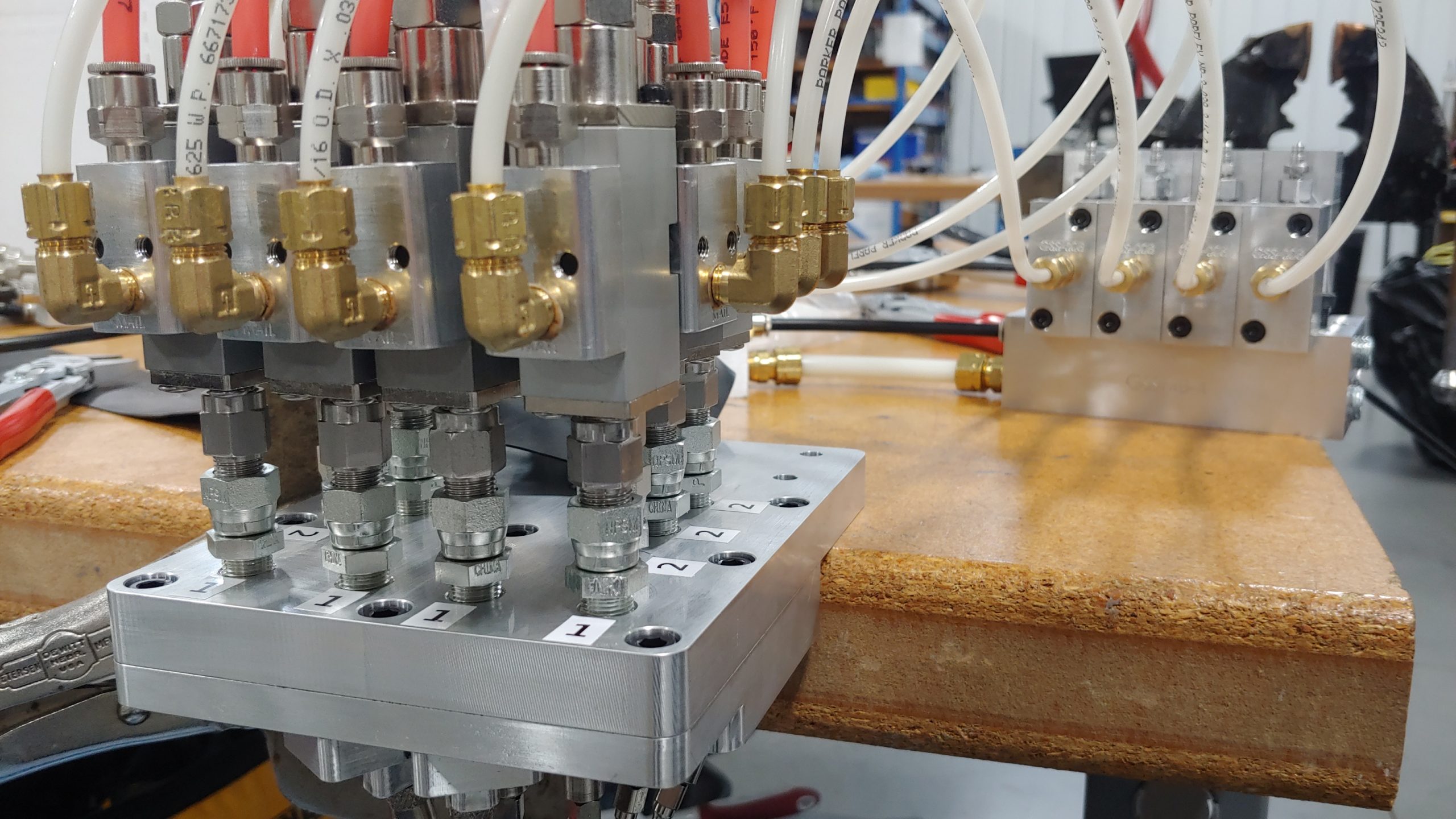

Proof of the Precision

We have partnered with a myriad of automakers to create various solutions for the industry’s production lines. Here’s just a few of the customers we’ve served with our advanced machinery:

Revolutionizing Production Dispensing for eMobility

The automotive landscape is continuously evolving, but the future of the industry is evident through the rapid growth of electrification. According to McKinsey & Co., by 2035, 65% of new car sales in the US are expected to be electric. For automakers, this implies a need for changes in assembly strategies and manufacturing processes. GP Reeves can help you accelerate your EV production with cost-effective and precise dispensing solutions. Learn more about how our systems can help you win the race to market on our EV webpage!

Our Process for Automotive Solutions:

The team at GP Reeves has collected decades of experience solving some of the automotive industry’s biggest challenges. We’ve partnered with a plethora of OEMs, integrators, distributors, and end users to create custom solutions for applications such as robotic seating rail greasing, lubrication of axle components, and adhesion of sensors to components of autonomous vehicles.-

- Analyze: Our experts work hard to diligently analyze the goals of each project and assess the needs of each component. The characteristics of each surface, material, environmental condition, and assembly part are carefully examined to make sure the most optimum solution is crafted.

- Design: Once a complete assessment of the project’s components has been conducted, our crew intricately designs each part of a dispensing system with unique capabilities, ensuring that it will maximize the potential of your production line.

- Assembly: After our team feels as though the design has exceeded our customer’s expectations, we manufacture custom and standard products in house, ensuring our system will effectively integrate with the customer’s current processes.

- Testing: GP Reeves replicates the eventual atmospheric conditions, materials, space, and any other factors to validate the process as best as possible.

- Continued Support: Even after we have verified feasibility and functionality, we also offer installation services and support for all our products. We are dedicated to your assembly line’s success for the long haul.

GP Reeves Customer Testimonial:

“I couldn’t be happier with your level of engagement and effort on this. I have to say, [a certain competitor] fell way short to matching your contribution. I’ll definitely lead with your solutions…”

Looking to improve your manufacturing process? Reach out for a free consult!

Case Study: Automotive Manufacturer Custom Nesting Integration

An automotive manufacturer approached GP Reeves after recognizing an excess of wasted material, labor time, and mess during the lubrication of window actuator components. They asked for a dispensing solution to increase simplicity and efficiency of their assembly process. Our engineers configured custom tooling that integrated into their existing automated system. The custom lubrication system accommodated the company’s unique grease material while accurately monitoring the dispense volume. By utilizing the unique dispensing capabilities of GP Reeves, the automotive manufacturer improved efficiency, effectiveness, and reliability of their assembly line and process. Our cutting-edge technologies have since been used in numerous other assembly processes for the same company, and we look forward to finding solutions and continuing to fuel progress in the automotive industry.

Which Area Would You Like to Elevate?

Our team has experience with supporting countless automotive components with our advanced dispensing technology. From dispensing micro-dots of material onto an HVAC part, to spraying the inner diameter of a driveshaft with our G-Force, to dispensing 2K adhesive onto the windshield of self-driving cars, we have both standard and custom solutions for all aspects of the automotive industry. Some of our favorite applications are highlighted below. If you don’t see your specific application, don’t worry, there are many more not listed, plus we always love a new challenge.Body & Exterior Assembly

Manufacturers have benefitted from increased quality, productivity, and profits through the integration of a GP Reeves dispensing system. We’ve successfully dispensed accurate volumes, pressures, and positions of all types of materials to the components of automotive bodies and exterior parts. We’ve effectively supported the processes of underbody construction, framing, roofing, and closure development. Our dispensing systems have propelled the development of components such as:

- Windshield Wipers

- Windows and Automotive Glass

- Sunroof/Moonroof Components

- Brake Lights

- Car Mirrors

- Door Structures

- Handles

- Security Mechanisms, and More!

Powertrain Development

Automotive developers have gained an elevated production capacity, more cost-effectiveness, and increased product longevity by utilizing dispensing systems from GP Reeves. We have experience with applications using a variety of dispensing materials in a wide array of environmental conditions. We’re well known for applying materials with the most optimal precision for:

- Gearboxes

- Transfer Cases

- Differentials

- Cardan Shafts

- Generators

- Combustion Engines

- Turbochargers

- Electric Motors

- Plug Connections

- Drive Shafts

- Charging Systems

- Gearbox Housings

- Crankshafts, and More!

Interior Design

When advancing the interior components of a vehicle, it’s important to ensure parts are durable, high-quality, reliable, and built to last. We’ve helped automakers gain a superior edge with our cutting-edge dispensing technologies. Our equipment has been used to deliver a wide range of materials to the surfaces of automotive interiors with extreme precision and accuracy. Examples of applications include:

- Interior Lighting

- Seat Components

- Display Panels

- Dashboard Parts

- Ventilation Systems

- Internal Mirrors

- Interior Door Panels

- Steering Components

- Automotive Electronics, and More!

Chassis Procedures

Increase chassis reliability and longevity with aid from dispensing equipment from GP Reeves. Our experts have created solutions for:

- Brakes

- Steering components

- Bearings

- Shock absorbers, and more

Electric-Vehicle (EV) Development

As the world transitions to a new way of constructing automotive components, GP Reeves continues to accommodate and support advancement. We’re capable of distributing material with intense accuracy to:

- Batteries

- Charging Systems

- Connectors

- Module Assembly

- Cover-to-Tray Assembly, and More!

Automotive Application Examples

For more details on these applications, check out our Automotive Applications page.

Need Something Specific?

We’d love to help! Provide a few details and your information in the form below and we’ll follow up.Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service