Grease Dispensing Products

Why Choose GP Reeves Grease Dispensing Products?

Most of our competitors pick a niche in the market and stick to it, maybe it’s just grease dispensers, or maybe they focus solely on custom nesting. We’ve never understood why someone would want to work with so many different companies to put together one grease dispensing system, which is why we have spent countless hours building up our product portfolio to include products for every part of the system.

Many of our customers choose to work with us because they know they can trust us with their entire dispensing system, from grease pump to dispense tip. On top of our vast standard product portfolio, we also offer custom nozzles, nesting, automation, and more. Our number one priority is ensuring that your part gets greased exactly how you want it, every single time. Some of the benefits you’ll receive from a GP Reeves grease dispensing product include:

Operational Efficiency

- Automation allows for larger containers which means less waste

- Checks and balances reduce human error

Production Capacity

- Larger containers allow for increased product output

- Low level sensors facilitate scheduled maintenance

Improved Product Quality

- Positive displacement ensures consistent application

- Less manual intervention guarantees material quality

Growth In Profitability

- Fewer turnovers reduce material waste

- Automated systems require less man hours

Workplace Safety

- Less human intervention means fewer workplace accidents

- Guards and covers provide added protection

Decreased Downtime

- Fewer material changes mean increased production hours

- Predictive maintenance decreases unplanned line stoppages

Initial Considerations

There’s a lot that goes into fluid mechanics, luckily, we’ve done the hardest parts for you. Our fluid dispensing systems work for greases between NLGI 00 and 3 (think ketchup to vegetable shortening). Plus, we can dispense some of the stickiest, chunkiest, greases out there. Before buying any product, it is important to know what exact grease you’ll be dispensing, this helps us recommend products that are compatible with your material.

When deciding which products will work best for your specific application there are quite a few things to consider. Some questions we consider you to ask yourself include:

-

-

-

How will you be purchasing your material? Is it coming in a drum, a pail, a bucket, or something else?

-

Where will you be applying the grease?

-

How detrimental will air or foreign debris in your material be to the application process?

-

What volume of grease will you need and at what rate will you need it dispensed?

-

How do you want the grease dispensed? Dots? Beads? As a spray?

-

Do flow, pressure, or volume monitoring need to be considered?

-

-

Let Us Help You Design The Perfect Grease System

Types of Grease Applications

GP Reeves has worked with a wide range of greases and has applied them to a plethora of surfaces. From our grease pumping equipment to our grease dispense tips, rest assured that the quality, reliability, and accuracy of our products has been proven time and time again. Our team of creators and innovators have developed solutions to optimally deposit grease lubrication to components of your most challenging applications. Additionally, we’re able to customize grease dispensing systems for even the most complex of grease materials. Some examples of grease projects we’ve successfully conducted in the past include, but aren’t limited to:

Robotic Dry Lube Spray Application

Dots on Automotive Bezels

Drive Shaft Inner Diameter

Kitchen Mixer Interior Lubrication

Building A System

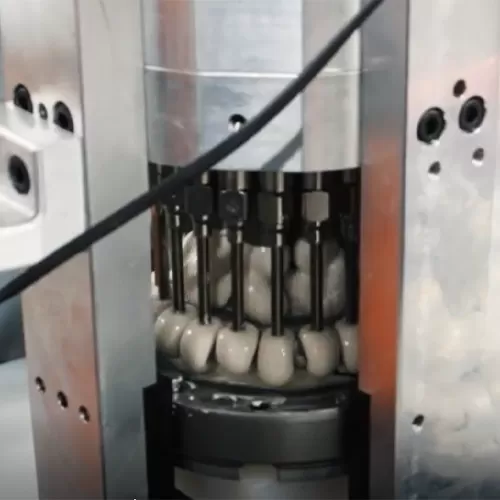

A complete GP Reeves grease dispensing system comprises at least 3 parts: the source, the dispenser, and the end point. Depending on how critical the application is, you may choose to add on a preparation product, or a confirmation device.

Purchasing a system from GP Reeves ensures that all of your products will integrate seamlessly, rather than trying to piece together several products from different companies. This will save your team time, along with the headache that comes from it. In addition to the ease of integration, our team will work with you each step of the way to make sure your products arrive safely and are running properly upon install.

Grease Source

The grease source is the first step in the fluid dispensing system. There are a variety of options for grease pumping equipment. Determining which product to use is highly dependent on what type of container your material comes in as well as the viscosity of your material. Thicker materials work best with dual post ram pumps. These grease pumps available in multiple sizes ranging from 1 to 55 gallons. For less viscous materials, a single post ram pump does the trick; our single post grease pumps are optimized for 15 gallon pails. Each one of these series has a variety of boost ratios, inductor seals, and other options available.

We also offer reservoirs/regulators. With high and low-pressure options available, these products can remove the need for a separate pressure regulator in your system. Plus, our manual series is designed to only require a temporary connection to a pump, which allows one grease pump to supply several reservoirs/regulators. If you’re not sure which options are best, contact us to figure out a configuration that will meet your needs!

Grease Preparation

In addition to pressure requirements, it’s recommended that you utilize a grease filter to ensure all unwanted foreign particles don’t make their way into your fluid dispensing system. Metal shavings and other objects can damage both the grease dispensing system and your part, so it’s key to remove them as early as possible in the process.

Grease Dispensers

GP Reeves offers a variety of dispensing options to fit the volume of material needed for your specific project’s needs. GSS and GPMD models of grease dispensers use a mechanical adjustment rod to adjust volumes. This works great for applications where the volume will be set and rarely adjusted.

For small outputs of less than 0.066 cc of dispensed grease material, GSS dispensers serve as great options. These fluid dispensers use adjustable volumetric piston displacement to quickly dispense measured shots of lubricant at up to 180 operations per minute.

The GPMD10000 series is perfect for medium output, low-pressure dispensing involving amounts of material from 0.02 to 6.20 cc. The GPMD10000 series offers base-mountable, air-operated, single-acting, adjustable, metered shot piston dispensers.

We also offer a GPMD3000 series dispenser with high inlet pressure, dispensing amounts from 0.05 to 210 cc.

Finally, our AA dispensers can dispense 0.02 to 1086 cc while detecting and rejecting grease-containing air. These positive displacement dispensers are available in pneumatic or servo options, and use a PLC to control the piston movement, which allows the PLC to control and adjust the volume. They dispense grease at controlled rates for even and distribution.

Our RotoMeter Dispenser series features versatile motor-driven dispensers that can be utilized in many types of grease dispensing applications. Progressive screw and gear pump designs are available.

Grease End Point

We’ve designed a variety of system end points to accurately dispense grease material to your part. Our snuff-back devices prevent oozing at the nozzle tip for cleaner applications. These work to make sure your lubricant is moved at an equal pressure. We also offer standard extrusion nozzles and custom-engineered nozzles/nests which have outstanding transfer efficiencies. GP Reeves also has air-assisted spray nozzles to help deliver precise amounts of grease in more challenging application processes. These nozzles atomize and spray material unlike other end points, which push material out.

Grease Accessories

GP Reeves offers numerous accessories to ensure that your fluid dispensing processes operate in a manner that is aligned with your optimal system. Our grease confirmation devices are used for redundant verification purposes and are based on your specific project needs. The three main categories of grease confirmation devices include flow, pressure, and volume. Flow confirmation devices are the most common and the simplest. They are helpful when users would like to double-check that material is flowing. Pressure confirmation devices are mid-level, and they are designed to confirm the correct feed or nozzle pressure of a system. Our volume confirmation devices are generally the most advanced. These confirmation devices confirm the precise volume of grease flowing through a specific device.

GP Reeves also offers accessories such as AA controllers, customized control packages, and remote support systems. Standard AA controllers are engineered to control one or two AA dispensers and allow for up to 10 user-defined part recipes. Our customized control packages can be designed to control as many AA dispensers as required along with the grease pump(s) to feed them. Lastly, a GP Reeves Remote Support system allows for remote connections to equipment for support. It can work with all major PLC/HMI manufacturers.

What Does it Look Like to Get a Grease Solution from GP Reeves?

The team at GP Reeves has collected decades of experience solving some of the biggest grease application challenges. We’ve partnered with a plethora of OEMs, integrators, distributors, and end users to create custom solutions for applications such as robotic rail greasing, lubrication of axle components, and grease applications for use with space technology. While we can dispense grease to a wide range of applications, the process for each looks similar. The steps we take to provide you with the ultimate grease dispensing solution include:

Analyze

Our team analyzes the characteristics of each surface, material, the environmental conditions involved, and each assembly part to ensure an optimal solution is crafted.

Design

After project analysis, our crew designs each part of the grease dispense system with unique capabilities, ensuring it will maximize the production line potential and provide an excellent grease solution.

Assembly

After our design exceeds expectations, we manufacture all products in house, ensuring our grease dispense system will effectively integrate with the customer’s current processes.

Testing

GP Reeves replicates the system’s eventual conditions, grease materials, space, and any other factors necessary to validate the fluid dispensing process.

Support

Even after we have verified functionality in our own facility, we offer installation services and support for all products. We are dedicated to your production success for the long haul.

Grease Dispensing Solutions Engineered For You

Whether you’re looking for an entire automated fluid dispensing system or a simple grease dispense tip, GP Reeves has the expertise, experience, and passion to ensure you receive the most advanced solution possible. Manufacturers around the globe are realizing the potential benefits that accurate, repeatable, and dependable fluid dispensing systems have on their assembly lines – are you? Get in touch with us today for a grease dispensing solution engineered for you.

Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service