Oil Dispensing Products

Central to our identity, oil dispensing is an intrinsic component of the GP Reeves brand. Starting from our roots, our debut product was a lube logic chain lubricator, which not only marked our entrance into the market but also set the stage for the relentless innovation our brand has championed since our conception in 1971. Fast forward to the present, while chain lubricators remain a valuable offering from GP Reeves and find utility across myriad industries, our strategic direction has evolved. Now, at the heart of our operations, the mainstay of our company revolves around ultra-precise dispensing systems. Echoing our global reach, our oil dispensing systems have garnered adoption worldwide, finding their place within the infrastructures of some of the most important industries today.

Why Choose GP Reeves Oil Dispensing Products?

The team at GP Reeves takes pride in our advanced oil dispensing capabilities. We understand the challenge of assembling a variety of standard products from different companies. To address this common hurdle, we’ve created all the necessary products for your top-notch oil dispensing system. Central to our offerings, our standard product line features oil reservoirs, pumps, dispensers, nozzles, and a vast array of accessories. Beyond this and complementing our standard product selection, we provide many custom solutions for exceptional oil material dispensing.

Diving deeper, the team at GP Reeves offers a broad product range to maintain and manage the oil material’s appropriate characteristics effectively. Spearheading industry advancements, our systems drive the innovations of many global manufacturing leaders, and we enjoy designing entirely new and customized systems for even the most unique applications. The feedback we receive from customers about our oil dispensing products is always outstanding, but some of the things we hear about most often include:

Improved Production Capacity

Enhanced Workplace Safety

Growth

In

Profitability

Improved Product

Quality

Faster

Production

Speeds

Decreased

Operational

Downtime

Video Transcript

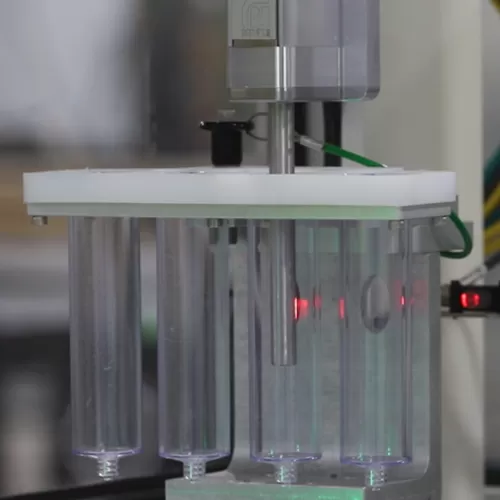

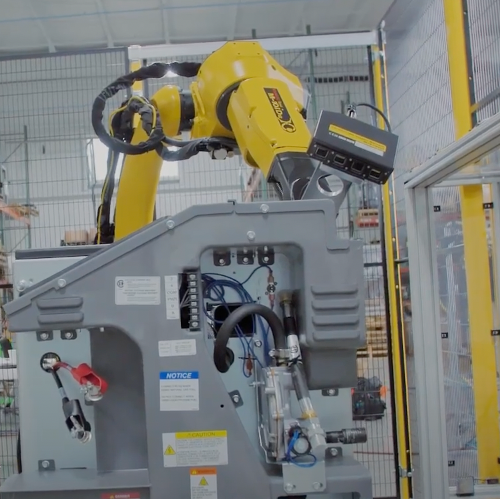

A generator manufacturer came to us looking for an automated filling system for their generator assembly process. The generators move down a conveyor belt and aren’t always in the exact same position- meaning our system would have to be smart. A vision system snaps two pictures of the generator and extrapolates the two-dimensional frames into a 3D map of the product. From there it is able to calculate the exact position of the opening to the engines and fill them with the precise amount of oil. Light curtains keep anyone or anything from entering during the fill process.

This system is flexibly designed to work with multiple generator models and can be modified to add even more in the future. This automated system is designed to save our customer time, money, and labor in their assembly process.

If you think that you have a problem that GP Reeves can solve feel free to contact us using the information below.

Initial Considerations

Fluid mechanics aren’t easy – we get it. Luckily, we’ve done the hard part for you. All you’ll need to know before designing an oil dispensing system with GP Reeves is what type of oil you’re using and where you want to dispense it. Our standard oil products will work for all types of oil, along with many other liquids. However, it’s crucial to provide the chemical makeup of your material so we can prevent any unwanted reactions.

After finalizing the material, the subsequent steps in system design become straightforward. The selection of a source primarily hinges on the oil’s packaging. For instance, if it arrives in a compatible container, a pump will suffice. Conversely, if the provided container doesn’t match your dispensing system’s needs, we have an array of reservoirs at your disposal. Furthermore, based on your application’s precision and importance, we also provide oil filters and regulators.

There are a variety of dispensers in our oil line. Choosing one will be based on your volume requirements and what type of feedback you’re looking for. Lastly, Nozzles and other end of arm equipment will be chosen based on what type of application you have, along with any other accessories.

Our Experience with Oil Dispensing

GP Reeves has been dispensing oil since day one! We’ve delivered oil to a wide array of surfaces and have been involved in the applications of a large variety of industries. We’ve developed the most innovative oil dispensing systems on the market to aid in the proper oil delivery. Some examples of our recent oil-delivery projects include:

Medical Syringes

Conveyor Chain Oiling

Dishwasher Motor

Generator Fill

Oil Dispensing System Examples

The most basic oil dispensing system consist of the pump, the dispenser, and the end tooling — whether that be a nozzle or a nest. Additional products could include a reservoir, a regulator, a filter, and some kind of confirmation device. We offer a variety of options for all pieces of your system.

When working with GP Reeves, we’ll ensure that you get the products that will optimize your oil dispensing system. From start to finish we can work with you to pick out the best products for your application and make sure it’s working just the way you had hoped once it’s installed

Oil Source

Before you can begin the process of dispensing oil, you must first get the material out of the original container. Our oil pumps are designed for effective and reliable production oil dispensing. The OR series is designed for gravity feed and is available in a variety of materials and sizes. The OPV series are oil pressure vessels with options for including a pump or sensor. The OPxR series includes a pump and powder coated steel reservoir. The OP series includes the pump that sits directly onto the pail or drum. The OPT tote pumps are designed to floor mount next to a customer provided tote. These pumps are available in a variety of boost ratios and sensor options for easy integration into the system.

Oil Preparation

GP Reeves offers innovative and efficient oil preparation systems to ensure material is properly dispensed with the specifics your operation requires. Our oil filters are always recommended, however they’re essential when pumping from a pail or barrel. The use of a filter helps to ensure that metal chips, foreign materials, and other debris are processed out of the material to make sure that it doesn’t jam up your dispensing system or get into your end product. Oil regulators manage the supply pressure to the dispenser so that material is supplied at the pressure most appropriate for your dispensing systems.

Oil Dispensers

We offer a variety of dispensers with options to meet any need. GSS, GSSM, and GPMD dispensers use a piston with manual volume adjustment. These are perfect for applications where the volume will rarely be adjusted once it’s set. GSS/GSSM oil dispensers are high-speed and can complete up to 180 operations per minute, they are designed for dispensing outputs less than 0.066 cc of oil. On the other hand, for medium-output low-pressure oil dispensing, a GPMD11000 series dispenser is perfect, with a volume range of 0.02 to 6.20 cc. For those seeking higher pressure, we recommend a GPMD3000L series oil dispenser, which is suitable with dispensing amounts from 0.05 to 210 cc. Our AA oil dispensers utilize a PLC to control the piston movement, which allows the PLC to control and adjust the volume, guaranteeing incredible precision. These dispensers are capable of dispensing 0.02 to 700 cc of oil while detecting and rejecting material containing air. They dispense at controlled rates for even distribution. RotoMeter dispensers can be utilized with pourable liquids that require measured or continuous flow dispensing; this series is ideal for filling applications.

Oil End Points

Drawing from a rich legacy, GP Reeves has harnessed years of diverse industry experience to meticulously engineer and develop endpoints that adeptly apply oil to the surface of your part. To begin with, we provide standard extrusion nozzles and custom-engineered oil nozzles and nests specifically for oil dispensing. Among this lineup, you’ll find oil spray nozzles, airless shot oil nozzles, and our G-Force oil nozzle, which sprays in a radial pattern. Importantly, these nozzles dispense oil on the part while minimizing the material left on the tip. Taking innovation a step further, our air-assisted oil spray nozzles are adept at addressing “challenging” applications; they don’t merely dispense – they atomize and spray the material. Additionally, GP Reeves also crafts end-of-arm dispense valves with a spectrum of applications in mind.

Oil Accessories

First and foremost, our engineers have dedicated their expertise to designing oil accessories that augment the precision and efficiency of your oil dispensing processes. For instance, our zone valves for oil allow one dispenser to supply material to multiple endpoints thereby facilitating the creation of larger systems with elevated flow rates. In addition, we feature ultrasonic flow sensors for oil which can seamlessly clamp around any nylon tubing in your setup. Within these sensors, ultrasonic waves diligently monitor material flow, and as a result, the volume dispensed gets displayed on the controller. Furthermore, we extend our offerings to both custom and standard controllers which are capable of controlling multiple dispensers. Integral to their design, these devices involve modes to control volume, pressure, and rate.

What Does it Look Like to Get an Oil Dispensing System from GP Reeves?

The team at GP Reeves has collected decades of experience solving some of the biggest oil application challenges. We’ve partnered with a plethora of OEMs, integrators, distributors, and end users to create custom solutions for applications such as robotic oil lubrication, oil applications to motor components, and oil delivery to advanced medical technology. While we can dispense oil to a wide range of applications, the process for each looks similar. The steps we take to provide you with the ultimate oil dispensing solution include:

Analyze

First,we analyze the goals of each project and assess the needs of each component. From surface characteristics to material specifications, our team will ensure the most optimum solution is crafted for your oil dispense.

Design

Next, once we conduct an application assessment, our crew designs each part of the dispense system with unique capabilities, ensuring maximum production line potential.

Assembly

Then, after the design has exceeded the customer’s expectations, we manufacture custom and standard products in-house, ensuring our oil dispensing system will effectively integrate with the customer’s current processes.

Testing

Most importantly, GP Reeves replicates the eventual atmospheric conditions, oil materials, space, and any other essential factors to validate that the oil dispensing process is functioning optimally.

Support

Finally, after feasibility and functionality are verified, we offer installation services and support for our oil dispensing products. We are dedicated to your production success for the long haul.

Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service