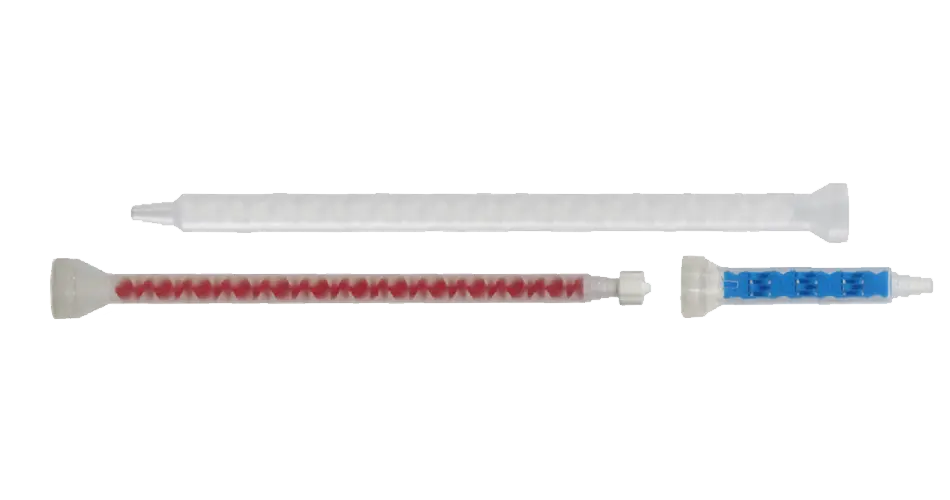

mixing nozzles for two component materials

Mixing nozzles allow your production material to reach its destination in the fluid dispensing journey. Accurate measurement is at the root of 2K dispensing. Our static mixing tubes come in various lengths, diameters, and end options to accommodate any two-component dispensing project. Direct your adhesives, sealants, thermal interface materials, and more toward part surfaces with confidence.

Features and Benefits

-

- Consistency: The geometrically designed elements ensure thorough and consistent mixing of the epoxy’s two components. This results in a consistent final product with predictable properties.

- Efficiency: The static mixer allows for continuous mixing and dispensing, streamlining the process and potentially increasing throughput.

- Precision and Control: Static mixing tubes allow precise control over the amount and rate of epoxy dispensed, ensuring that only the required amount is used for a particular application.

- Versatility: Static mixers can be used with various epoxy viscosities and formulations, making them versatile tools for different epoxy applications.

- Convenience: Disposable design allows for minimal cleaning or maintenance.

Configuration Options

-

- Tapered, stepped, and Luer lock tips available – lengths from 3″ to 9.15″, outer diameters from 0.370″ to 0.494″, and various fold configurations and shapes.

- Hydrophobic polyester inserts for moisture-sensitive materials.

- Compatible with all common ratios.

- Round and square tubes offered.

Product Details

GP Reeves’ static mixers allow you to dispense materials with ease. Our various mixing nozzles, including our epoxy mixing nozzles, are equipped for efficient mixing, precise delivery, and consistent results. Our mixing tubes come with one of three end types: tapered, stepped, or luer lock. One end type might be better depending on the size and precision needed. If the accuracy of the dispensing process is crucial, a luer lock nozzle will serve you best. A tapered mixing tube allows controlled dispensing but not necessarily the precision obtainable with luer lock ends. Lastly, stepped tip mixing tubes allow customization of your bead size since you can trim the tip opening to the necessary diameter. Each mixing nozzle type is dependable and efficient but can serve your assembly line differently.

LOOKING FOR More 2k ADD-ONS?

Mixing Shroud

Marrying Block

Ratio Test Nozzle

Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service