Our Process

Collaborating with integrators allows GP Reeves to assist with a wide array of manufacturing endeavors. From comprising one cell of a mile-long automation track, to providing equipment for a single robotic arm, GP Reeves has completed a myriad of complex projects for integrators and our team can effectively advance even the most complex industries forward. We’re cognizant that integrators have an extensive knowledge of equipment and production processes, and we want to make the integration of GP Reeves systems within their processes as simple and easy as possible. Therefore, we’ve developed a process for working with integrators and ensuring they receive the best dispensing solutions possible.

Initial Examinations

GP Reeves understands the importance of gathering all information about even the most minuscule project details. Our team wants to promote as much success as possible, so we meet with integrators to discuss the scope of the overall project, any specific goals or concerns the integrator might have, and the hopeful end process they wish to achieve. Even the most challenging of specifications can be met by our ability to customize equipment, meaning our engineers are prepared to serve customers with a solution that will meet even the most niche project needs.

Encouraging Collaboration

Customer feedback is crucial to our success, so we diligently work to provide concept designs that the integrator and customer can review and approve. If anything is not to the client’s liking, our engineers work relentlessly until they’ve developed a concept that is satisfying. We ensure that all standard and custom aspects of the project are pleasing to the integrator’s particular desires, and we can continue to configure and customize as needed. Once a customer is pleased with our dispensing proposals, we’ll offer a final description of the process and present our progressive solution to the integrator’s team.

Continued Reliability

The team at GP Reeves has been revolutionizing the ways integrators provide innovations for over 5 decades. One way in which we do this is by continuously supporting the customer and their projects. Our engineers will ensure the integrator has all mechanical components they need from us, such as mounting and programming, and we’ll configure solutions to make things as easy as possible. We are extremely vigilant about how our project will fit into the integrator’s overall system and will utilize a keen attention to detail to ensure processes are efficient and effective.

Effective Finalizations

Once GP Reeves has manufactured a solution fit for the integrator’s most complex needs, we test the system at our state-of-the-art facility and invite the customer to come in for a full run-off. We want customers to be completely gratified by their solution and will continue to work on project concepts if the run-off doesn’t meet every need. Additionally, we have the capacity to test our system within the integrators assembly line to ensure full integration success.

Endless Dependability

Even after GP Reeves has shipped out the integrator’s solution, we continue to offer support. Our team is willing to train any operators and users involved with the dispensing system to properly ensure all individuals can effectively maintain and utilize GP Reeves dispensing equipment. Additionally, our team will always be thrilled to provide constant support in the long run. GP Reeves will continue to offer support, maintenance, and training, for the solution’s entire product lifetime, and even further if future project updates, upgrades, or completely new configurations are needed!

Examples of our Work with Integrators:

GP Reeves has collaborated with a multitude of integrators to cultivate the perfect dispensing solution for a variety of automation challenges. Our engineers have created successful dispensing systems that simply attach to an already programmed robot as well as entire completely custom automated dispense cells. No matter your dispense automation needs, our team is more than willing to tackle the challenge. Here are just a few of our automation dispense capabilities and examples of how we effectively partner with some of the globe’s biggest integrators:

Dispensing for an Entire Automation Line

Oftentimes integrators will come to GP Reeves seeking a solution that they can integrate into their already designed assembly concepts. When this happens, our engineers will customize an advanced dispensing system that will be integrated into the specific cells of the customer’s production line. Our team observes every intricate detail of examples from other aspects the integrator is working on for that line to ensure the overall look and functionality of the products we configure will match the rest of the line’s look.

We work closely with the integrator and end user’s engineers to consider all the dispensing needs that the overall project has. Many times, with projects like this, a lot of the equipment we product is very customized to the end user’s specific parts, whether this be custom tooling and nozzles, or specialized dispensers and pumps. There are a variety of factors taken into consideration, such how parts will be delivered, whether it be manually or automatically. We also confirm if our data needs to be sent to the main PLC, if we need to send dispense data to any other PLCs, or if other equipment will be sending any information to our PLCs.

For example, one integrator was creating an assembly line that consisted of about a mile’s worth of automation cells. GP Reeves configured dispensing solutions such as dispensers, pumps, and confirmation devices that were then integrated into the company’s assembly process. For this process, the team at GP Reeves considered every unique aspect of the customer’s production line and customized machinery to meet the needs of each cell. In the end, the integrator was enthused about the ease our considerations brought to their assembly process.

Configuring a Complete Dispensing Cell

GP Reeves pays special attention to ensure concept delivery is exactly as the integrator expects – if not better. We’re sure to consider how parts will enter our dispensing cell, whether this process will occur automatically or manually, how the controls of our cell will interact with the rest of the line, if certain dispense data should be passed on, and if there is a certain method parts will be required to exit our dispense cell. To ensure customers receive the most advanced dispensing cell possible, we emphasize the importance of a full and detailed understanding of exactly what the integrator has planned for the rest of their design. With this, we cultivate a complete dispense cell that will easily integrate with the rest of a customer’s assembly process.

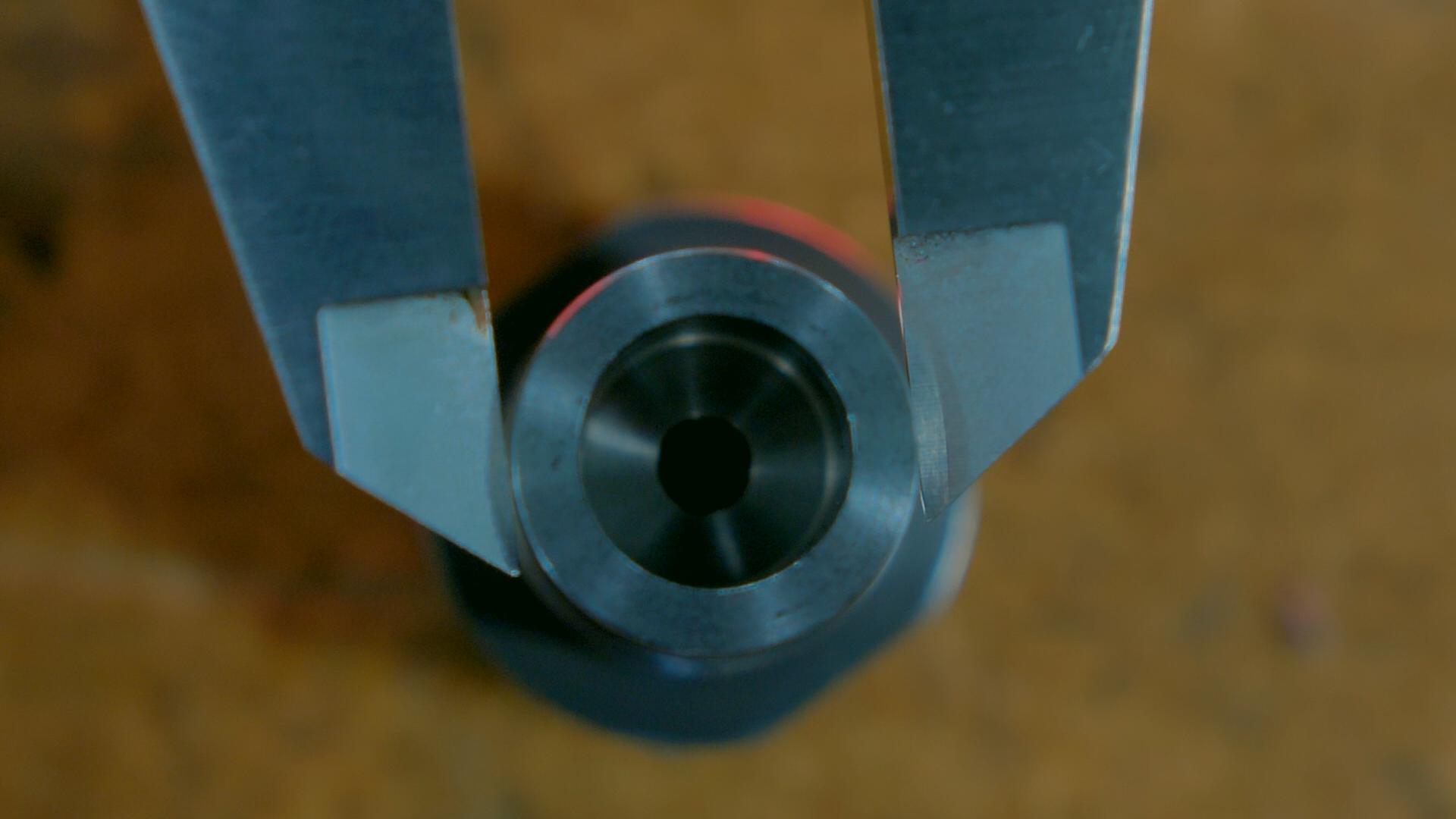

Integrating with Robots

If a customer already has robots and cells ready, GP Reeves will happily customize dispensing equipment to attach to the integrator’s cell. Our team can add dispense equipment to the cell and then provide controller programming for the robot if desired, or we can simply provide tooling and dispense equipment. GP Reeves can customize our dispensing solutions to ensure every aspect of the customer’s cells are properly considered. Our dispensing company is known for its innate ability to perfectly customize tooling and dispensing systems to meet the exact and unique needs of each customer, and this is no different when it comes to robotic components. Whether we’re providing the rest of the automation cell with nozzles and tooling or a full dispense system, we’ll intentionally consider each aspect of the cell and the entire assembly line in general.

Our Results

GP Reeves has grown exponentially since its inauguration into the dispensing industry. This is mainly due to the results that can be expected of our dispensing products and the experience offered to customers when collaborating with our dedicated team. We provide the custom, advanced dispensing systems our competitors can’t even imagine. Our systems have led the way for innovation within the automotive, medical, aerospace, renewable energy, consumer products industries, and more. If you’d like to collaborate with us on a solution best fit for you, get in touch with one of our experts today!

Interested in Our Products?

Fill out the form below and we'll follow up with you!