Where To Begin?

Lubrication is an essential part of furthering the life of your conveyor, so it’s important to have the equipment that will do it right. Thankfully, GP Reeves knows a thing or two about lubrication (we have been perfecting it for over 50 years now). We have assembled a handy list of ten key features a manufacturer needs for a great lubricator.

Nozzles

The lubricator should airless squirt lubricant into conveyor wear areas. Included modified conveyor track section should have pre-aimed and clamped nozzles. If the lubricator has a brush or brushes instead of nozzles, it will smear oil on the conveyor, but not into it. Customer should not have to engineer the installation.

Dispenses “All” Lubricants

The lubricator should be able to squirt ISO 2 – 100 lubricants. Too many lubricators can squirt only the thin “dry-film” lubricants.

Multi-Directional Operation

The lubricator must be capable of operating in either conveyor travel direction so it can be installed with its “front” accessible where you want it on the conveyor. If the lubricator includes a single arrow, it can only be installed one way.

Included Controller

The lubricator should have an advanced microprocessor with programmable display screen to allow lubrication based on counting complete conveyor circuits. Timed lubrication is not as accurate as counting and the OFF and ON times are often not even based on conveyor run time.

Powered by Compressed Air

Compressed air is common in most industrial facilities and is the best source of energy for the reciprocating piston motions necessary to accurately measure and squirt lubricants. Electric lubricators usually can’t squirt all lubricants.

Adjustable Positive Displacement Dispensers.

Because not all conveyor components require identical amounts of lubricant, the lubricator should have an adjustable positive displacement measuring dispenser for each lubrication point. Some electric lubricators connect two or three nozzles to the timed lubricant output of one solenoid valve and the amount of lubricant squirted from each nozzle is not controlled.

Modifiable Velocity

A compressed air regulator allows the ejection force of the lubricant to be adjusted to squirt all viscosity lubricants without dripping or splashing. Some electric lubricators are not capable of squirting both thick and thin lubricant.

Check Valve at Each Nozzle

Each nozzle has a check valve located as close to its tip as possible to eliminate dripping. Having only one nozzle tip downstream of each check valve is an essential factor in eliminating dripping. Many electric lubricators use “capillary” tubing and connect more than one nozzle to the output of each solenoid valve. This invites dripping because lower nozzles siphon lubricant from higher nozzles.

Auto-Speed Shot Placement

The lubricator recognizes conveyor speed and automatically places the lubricant in the correct locations on the moving conveyor components regardless of conveyor speed. Squirt type lubricators without this feature require manual sensor adjustment after every speed change.

Auto Fill or Central Reservoir

The lubricator has an integral reservoir that includes ports to allow automatic filling from a remote source. The lubricator may also be designed without an integral reservoir to function with lubricant supplied by a remote pump. Lubricators that use the lubricant supply pressure to obtain the force necessary to squirt lubricant are usually limited to operation only with thinner “dry-film” lubricants.

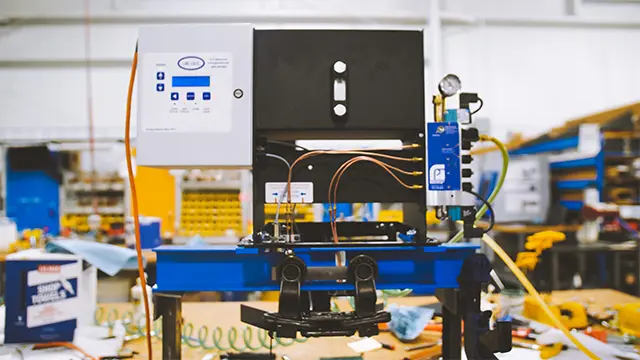

Let’s Get Started!

Now that you know what you should be looking for in a lubricator, you’re probably thinking “Where do you find one that has it all?” Look no further than right here! Our LubeLogic Chain Lubricators were the first product in our portfolio dating back to the 1970’s. With options for various types of conveyors and chains, there’s sure to be one that meets the needs of your facility. Contact us with any questions or to get assistance in identifying which lubricator is best for your facility!

Have Questions About Chain Lubrication?

Fill out the form below and we’ll follow up with you!