There are several types of material dispensers available for the manufacturing process. The most common types are positive displacement dispensers and time/pressure dispensers. Both types have advantages, but when it comes to precise dispensing, positive displacement dispensers often take the crown. The accuracy, decreased waste, versatility, and volume control offered by positive displacement dispensers make it the optimal choice for many manufacturing systems.

Positive Displacement

Positive displacement covers a wide variety of dispenser types but generally refers to the movement of pressurized material through an enclosed chamber via mechanical means. The action can come from pistons, gears, or screws. The automated nature of positive displacement dispensers allows them to operate at a higher level of precision than a time/pressure dispenser. Choosing a type of positive displacement dispenser is entirely dependent on the application. Gear, screw, and peristaltic pumps allow for continuous flow, whereas piston pumps can only dispense a volume as large as the piston but with a higher level of accuracy.

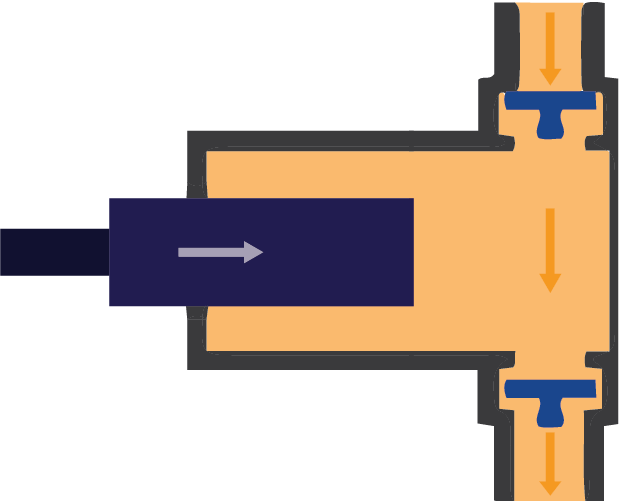

Piston

Piston-driven positive displacement dispensers consist of a pressurized chamber and a volumetric piston. When the piston pulls up, pressure in the chamber decreases, and the valve draws fluid into the main compartment of the dispenser. As the piston moves back down, pressure increases, and the piston forces material equal to its swept volume to exit the chamber through one or more configured valves. Piston dispensers can repeat this process in a variety of pressure settings and can operate with highly viscous materials. The mechanical nature of this operation allows it to repeatedly dispense accurate volume despite material variants such as temperature or viscosity.

Dispensers that are piston-driven are ideal when dispensing singular shots. Something to be aware of with this dispenser is that the shot size can only be as large as the piston. GP Reeves manufactures dispensers with pistons over 1000 cc; however, if your application requires a large amount of material very quickly, a rotary dispenser may be better suited.

Rotary

Positive-displacement rotary pumps offer an excellent method of continuous flow dispensing. These utilize rotary motion instead of reciprocating motion for operating, like other positive displacement options. Rotary pumps do not require check valves since a dynamic seal exists to provide for the continuous flow of material. After the material enters the chamber, it moves from the suction side pump to the exit side of the pump. There are several types of rotary pumps, including gear and peristaltic pumps. Both versions pump high-viscosity fluids with minimal reduction in efficiency and durability.

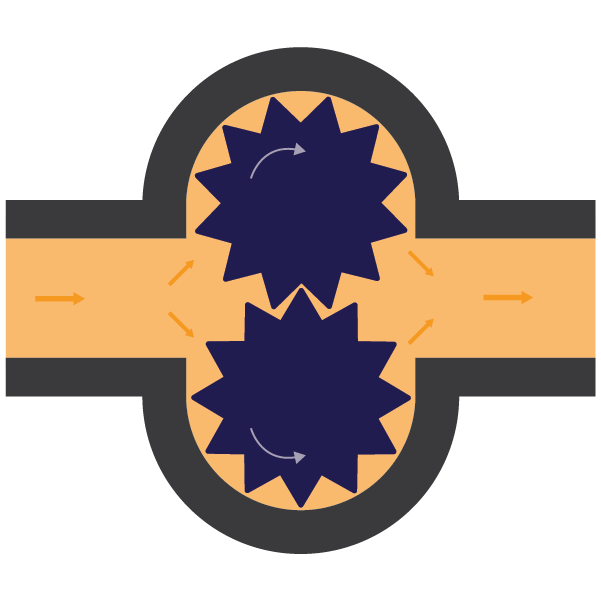

Gear

The material moves through gears, ensuring it is accurately transferred and minimizes leakage. Internal and external gear pumps are available. Both types have two internal gears. The internal type of pump features one gear inside of another; the material will flow inside the larger gear and be moved by the smaller gear. External gear pumps feature two gears that sit next to each other; material flows around and between these gears—our VFMG series of flow sensors functions in this way. Gear pumps generally need consistent calibration to account for the wear of the gear in the volume measurement.

Internal Gear Pump

External Gear Pump

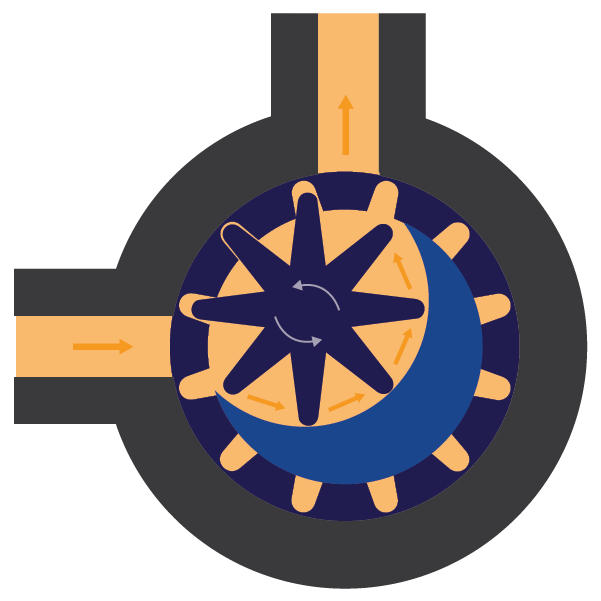

Peristaltic

The pump chamber contains a flexible tube (light orange) that transfers material around its outskirts. The pump’s rotor (dark purple) has rollers on its outer edge that compress the tube and continuously push the body of fluid. Peristaltic pumps ensure accurate volume measurement using the amount of tubal space between each roller. These pumps are suitable for corrosive or reactive materials because the pumped material touches only the tube, and you can customize the tube material for each application.

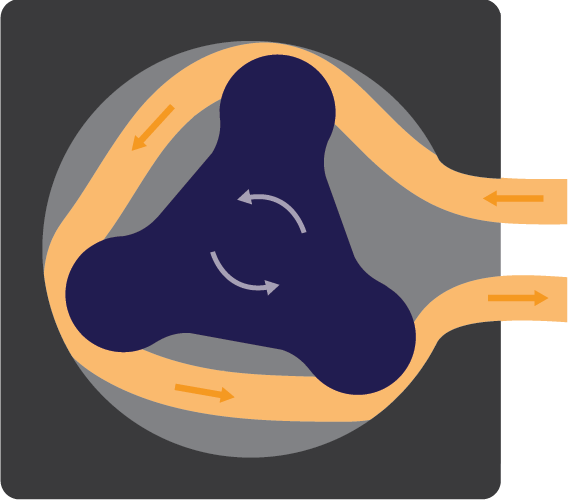

Progressive Screw

The material moves through the chamber in the cavities of a screw. As the pump’s rotor turns, material flows from cavity to cavity with a flow rate proportional to the rotation rate. As the amount of fluid in one cavity dwindles, the volume of another simultaneously increases, so there is no pause in the overall flow process.

Many GP Reeves products utilize positive displacement technology. Most of our dispensers are piston driven, some oil sources utilize diaphragm pumps.

Time Pressure Dispense

Time pressure dispensers work by moving material under pressure through an “Off-On” valve that is opened and closed by a solenoid valve controlled by a PLC or electronic timer. Sometimes, people add pressure regulators and adjustable orifices to monitor or control the flow rate. Time pressure dispensers function like a faucet and require constant volume monitoring to remain precise.

Material flow characteristics are often unpredictable, meaning timed dispensers need to be more capable of accuracy and repeatability for them. Thicker materials move significantly slower than thin ones, so they dispense less thick material in the same time frame. External variants such as temperature and humidity can impact the viscosity of materials throughout a single day, leading to inconsistent dispense volumes when utilizing a time pressure dispense system. The exact volume of how much material is dispensed on the part would be unknown unless a weight is measured of each part before and after the dispense.

If precision and repeatability aren’t a top priority, a time pressure system may work fine for your application; however, if repeatability (down to the hundredth of a cc!) is essential, positive displacement dispensers are the way to go. Positive displacement systems offer advantages that cause production lines to be more efficient, sustainable, and accurate. Luckily, the GP Reeves team is committed to innovating positive displacement to the top of its game by providing only the most optimal solutions for each application. The mechanical innovation of our positive displacement systems ensures your assembly is conducted with cutting-edge precision and repeatability. Whether a piston, rotary, or diaphragm pump makes the most sense for your manufacturing process, you’ll be guaranteed extensive care and quality from a GP Reeves dispense system.

Interested in a Positive Displacement Dispensing System?

Fill out the form below and we'll follow up with you!