Resources

From case studies, to fluid mechanic deep dives, to employee spotlights, to general business info, our resources page is the place to find any and all GP Reeves news.Ten Features of a Great Lubricator

Lubrication is an essential part of furthering the life of your conveyor, so it’s important to have the equipment that will do it right. Thankfully, GP Reeves knows a thing or two about lubrication (we have been perfecting it for over 50 years now). We have assembled a handy list of ten key features a manufacturer needs for a great lubricator.

Solar Shingle Dispensing, Simplified

Direct access to solar energy at your home has several benefits including lower utility bills, increased market value, and self-sustainability. However, typical solar panels can be bulky and out-of-place on a residential house. As the demand for residential solar power increases, manufacturers globally are working to improve the appearance and functionality of solar panels. GP Reeves worked with a manufacturer who designs solar panels to mimic the look of standard roofing shingles.

Dispensing Innovations For Advanced Air Mobility

Innovations in aerospace technology, enhanced commercial focuses on decarbonizing, and the evolution of electric mobility will accelerate the momentum of advanced air mobility. An area where this segment’s innovative transformation is evident is that of electric vertical takeoff and landing aircrafts, known as eVOTLs. One of the many companies attentive to the growing eVOTL adoption rates has developed its own solutions for eVOTL technology. To simplify their assembly and ensure an efficient manufacturing process, they came to GP Reeves seeking a custom automated dispensing solution.

Scary accurate dispensing for Halloween

There is a biting chill in the air, and there are Jack-o-Lanterns on every front porch. It might be Halloween, but there’s nothing scarier than…. IMPROPER MATERIAL APPLICATION!!! Okay, there are scarier things than that, but products that aren’t properly lubricated, sealed, or adhered can put a damper on holiday festivities.

Critical Preventative Lubrication Maintenance

Critical preventative maintenance lubrication is an integral part of equipment upkeep. While necessary, some issues can come up during the machinery lubrication process, making it more difficult, time-consuming, and expensive than necessary.

GP Reeves has partnered with numerous manufacturers to configure lubricant dispensing solutions that promote ease, reduce downtime, and increase productivity. Here are some problems our customers have dealt with and our way of flipping the script!

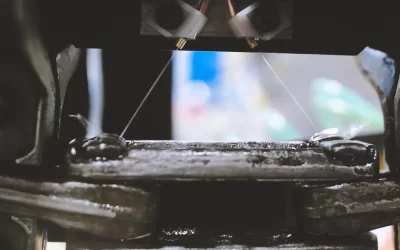

Pellet Mill Lubrication: Clean Grease, Simplified Process

An animal feed manufacturer came to GP Reeves for assistance with maintaining their feed pellet mill. We developed a grease dispensing solution that applied food grade grease to roller, die, and drum components of the pellet maker. Our process improved the quality of the manufacturer’s machinery, saved material, and simplified the necessary maintenance.

Building Good Customer Relationships

When you satisfy the mechanical needs of a customer, you can excel as a business. But when you exceed customer expectations with friendliness, prestigious service, and a willingness to go the extra mile, you can excel as a whole. GP Reeves is dedicated to ensuring that customers have an incredible experience whenever they choose to partner with us. We want to ensure that their experience is consistent with each project and that our partnership is secured for a lifetime.

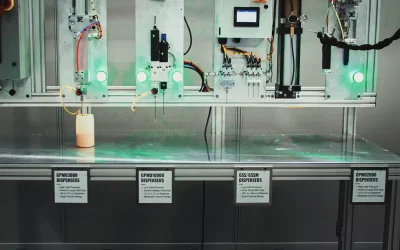

Renewable Energy Solutions: Degassing Process

Renewable energy is paving the way for a sustainable future. Though there are obvious benefits of transitioning towards renewable options, one of the most talked about problems regarding renewable energy is the inconsistency. However, this is solved through energy storage systems. Recently, we were approached to assist in developing an automated filling solution that not only measures and dispenses their electrolyte solution but degases the material as well.

Servo vs Pneumatic Fluid Dispensing Comparison

GP Reeves has accumulated a wealth of experience in precision dispensing since its founding in 1971, and since then, our team has grown to provide global industry leaders with a variety of effective dispensing solutions. Our typical fluid dispensing solutions involve positive displacement pneumatic or servo dispensers. Join us for a deep dive into these concepts, where we’ll explain servo vs pneumatic dispensing and how they contribute to the success of your production line!

Optimizing Santa’s Workshop with Automated Dispensing Systems

As manufacturing processes continue to evolve, a lot of smaller mom-and-pop shops want to keep up with the times but aren’t quite sure where to start. Though there are lots of processes that could be semi or fully automated, we believe material dispensing is a great place to start. In the spirit of the holidays, we’ve outlined how we would help Santa optimize his workshop, allowing his elves to spend more time on the fun stuff – like hand carving a rocking horse.

Thanksgiving Dinner’s Partner in Dispensing

Thanksgiving dinner is one of the most iconic meals in America. Weeks of planning, days spent cooking dishes for a single meal. You might not realize it, but GP Reeves is working in the background to make this holiday go smoother.

Making It in Manufacturing: The Expert Guide To Success

Getting started in the field of manufacturing can be quite the uphill battle. Because GP Reeves is cognizant of the hardships the manufacturing industry can provide, we want to make it as easy as possible to start off on the right foot! Think of us as your big brother in manufacturing, we want to help you as much as possible and to do that, we’ve gathered some advice from some of our top professionals to guide you along.

Boats Built Better | Wire Harness Case Study

As the world progresses into a new technological epoch, many recreational boat manufacturers are seeking ways to incorporate automated reliability into their production lines. A leading marine manufacturer came to GP Reeves seeking a solution to further their marine development with advanced dispensing. We were able to deliver a customized, turnkey, semi-automated dispensing system that allowed for a higher production capacity, increased product quality, and faster assembly efficiencies.

Sustainable Dispensing Materials

As the globe increasingly shifts its focus towards sustainable efforts and renewable technology, it’s important to recognize the many ways through which manufacturers can implement environmentally friendly options into their production assembly. One of these ways involves the utilization of biodegradable materials. There are several materials coming to market that provide a biodegradable and compostable method of bonding, sealing, lubricating, and more. GP Reeves can effectively dispense these progressive materials with our advanced dispensing systems, and we can’t wait to see how they’ll help the industry become more eco-friendly!

Oil Filling Assembly | An Automated System Solution for Generator Engines

For a commercial-grade generator manufacturer, GP Reeves designed an innovative oil fill system that provided accuracy, efficiency, and unbeatable reliability. This system recognized differences between various models and ensured each component received the proper amount of material every time.

Custom Solutions From Start to Finish

GP Reeves prides itself on its remarkable ability to solve even the most challenging of material applications. Along with our wide array of innovative standard products, GP Reeves offers custom equipment options and configurations. From a single custom nozzle paired with a standard pump and dispensers, to an entirely custom automated dispensing system, GP Reeves can develop an effective and reliable solution for you.

GP Reeves: Made in the USA

GP Reeves prides itself on its position as an established member of the American supply chain. As this year’s Independence Day approaches, we are grateful to celebrate our ability to manufacture and distribute precision dispensing equipment in the United States.

Why Positive Displacement is the Key to Precision

There are several types of material dispensers available for the manufacturing process. The most common types being positive displacement dispensers and time/pressure dispensers. Both types have their perks, but when it comes to precise dispensing, positive displacement dispensers often take the crown.

Innovative Rotor Assembly | A Solution for Electric & Hydrogen Powered Vehicles

A manufacturer came to GP Reeves seeking a solution for the assembly of electric and hydrogen powered vehicle drivetrains. Their motors, found in the vehicles all over the globe, needed a dispensing system as innovative as their impact on the transportation industry.

Integrating Success

GP Reeves is proud to work with a variety of integrators to ensure they receive the best dispensing system possible for their unique production needs. From single dispensers to entire robot cells, GP Reeves is happy to help integrators create the best assembly solution for their application.

Interested in Our Products?

Fill out the form below, and we'll follow up with you!

Contact Us

(616) 399-8893

customerservice@gpreeves.com

4551 Holland Ave, Holland, MI 49424

Service