Nobody likes to clean up a mess. It causes frustration, downtime, wasted material, expenses, and a loss in production capacity. An integrator came to GP Reeves seeking a solution to a troublesome RTV application process. The company was attempting to apply RTV material to the transaxle housing used by John Deere tractors and XUVs. These vehicles provide operators with reliable ways to effectively clear land, care for livestock, cultivate crops, and complete harvests efficiently. Although they might do the dirty work, their assemblers shouldn’t have to.

The Problem: Messy and Inconsistent Application

Initially, the integrator utilized a time pressure system to dispense the RTV material with a luer lock tip. The time pressure system had speed limitations, volume inconsistencies, and vulnerability to changes in viscosity and temperature. The luer lock tip was not zero-cavity, so there was an inappropriate allowance for oozing and wasted material. These struggles multiplied when noting the influences of the RTV’s characteristics. RTV is a type of rubber that reacts to form a cured and hardened adhesion to a surface when exposed to an environment at room temperature. So, when processed with the inadequate operations of the previously used time pressure system and luer lock valves, the RTV cured and thus clogged the machinery. Cleaning up clogs and fixing machine components took labor, expenses, and time. Unfortunately, this effort often resulted in inaccurate bead dispensing. The time pressure system allowed air to enter the cavities of its parts and nozzles, and this air created gaps in the RTV material as it was dispensed onto the transaxle’s surface. After realizing the amount of waste, cost, and havoc this process was causing its production line, the integrator reached out to GP Reeves to seek a solution to this unnecessary mess.

The Challenge: Applying a Unique Material with Customized Conformity

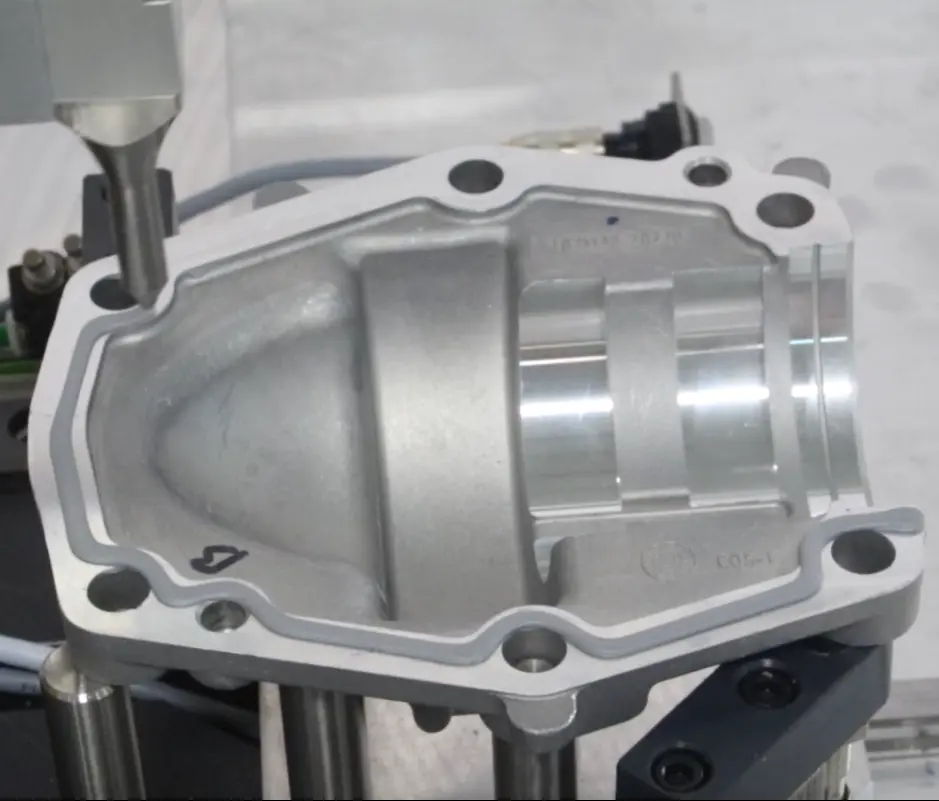

Materials that maintain a machine’s durability and reliability are critical in developing transaxle components for tractors and XUV systems. As an example, a transaxle contains a housing cover that is bolted onto the transaxle housing directly. The housing contains oil which needs to be carefully contained. Because RTV provides a durable yet flexible bond, it is the best solution to prevent potential leakage. RTVs are able to withstand the mechanical stress and weathering often faced by transaxle components.

However, RTV can be challenging to work with on the process side of the procedure. The material cures and hardens when it meets the atmosphere’s naturally occurring moisture or comes into contact with a room-temperature environment. Thus, proper maintenance is crucial and creates new challenges during manufacturing. Additionally, RTV is susceptible to air bubbles. Air exposure to the mix of RTV material causes gaps in material flow and dispensed product. This unique and complex material needs to be managed carefully and requires attention to detail by its manufacturers. To properly execute RTV dispenses, the machinery components must all accommodate the needs and requirements of the integrator’s preferred RTV product.

The Solution: Automated System from GP Reeves

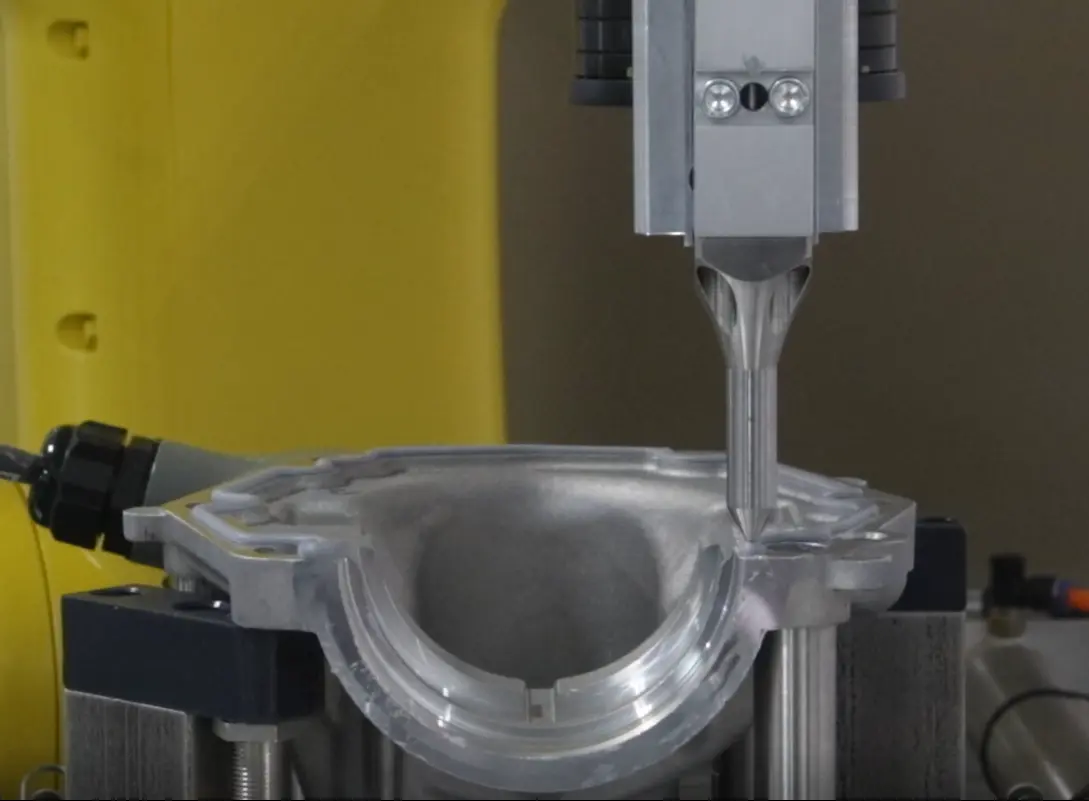

GP Reeves developed a solution to provide the ultimate process for the integrator’s challenging RTV application. Our engineers solved the integrator’s main problems of inaccuracy, early curing, and maintenance expenses with our advanced dispensing systems. For starters, we used our patented air check compression test eliminating possible inaccuracies due to the presence of air. Since air would now be monitored and checked, the RTV material would no longer suffer from gaps, and lines of dispensed material beads would no longer be thrown off. Our automated dispense machinery ensured that dispenses occurred with repeatable accuracy, so the flow, volume, position, and pressure of material were the same across dispenses, and all beads were uniform. Operators could trust the reliability of GP Reeves machinery no longer having to deal with dispensing mistakes or clean-up.

GP Reeves circumvented the original system’s issue of premature curing with zero-cavity dispense valves, ridding the possibility of the RTV material meeting moisture or room-temperature conditions before its proper dispense time. The system utilized an AA7 dispenser, which has been developed to accommodate materials with moisture-cure potential. The system’s pump was air-operated with a single post ram that included an inductor seal to ensure even more intentionality for properly maintaining material. Attention to detail and expertise ensured the RTV material and its curing factors were adequately considered in this dispensing process.

GP Reeves was also able to circumvent the original system’s issue of premature curing with zero-cavity dispense valves, effectively eliminating the possibility of the RTV material encountering moisture or room-temperature conditions before its designated dispense time. The system utilized an AA7 dispenser, which has been specifically developed to expertly handle materials with moisture-cure potential. The system’s pump, operated by air, featured a single post ram inclusive of an inductor seal to ensure even more careful management of the material. Our meticulous attention to detail and years of expertise ensured that the RTV material and its curing factors were appropriately handled in the dispensing process.

Finally, GP Reeves was able to decrease the maintenance required for the dispensing process with its innovative technologies. Thanks to our unique zero-cavity dispense valves, operators no longer had to cope with oozing material and the cumbersome task of cleaning it up. The servo dispenser we implemented ensured consistent, controllable dispenses, leading to beads with uniform widths and positions. This allowed assemblers to complete the transaxle development process more effectively with minimal concern about inaccuracies. The automated dispense system was also capable of adjusting its rate of dispense based on both the location and timing of the dispense, enabling it to effectively dispense the RTV material onto and around different positions of the housing structure without manual interference. In essence, our team was able to significantly reduce the integrator’s downtime and maintenance needs with our clean, accurate, and reliable automated dispense system.

End Results: Reliable Repeatability

By implementing an automated dispense system from GP Reeves into their assembly line, the integrator was able to expedite the assembly process of transaxle housings. These crucial components found their way into robust farming vehicles across the globe, rendering them ready for operation more swiftly and effectively. This streamlined process not only boosted the efficiency of the assembly line but also enhanced its sustainability and productivity. The financial implications were equally impressive, with significant savings made in terms of maintenance, labor, and material wastage. This level of optimization brought about by our advanced dispensing machinery allowed the integrator to produce world-class products at a speed and quality level previously unattainable. At GP Reeves, our aim is to drive you towards your goals, and this project is a testament to that commitment. We invite you to see how our technology can turbocharge your assembly line and help you reach your business objectives. Connect with us today!

Interested in upgrading your current dispensing process?

Fill out the form below and we’ll follow up with you!