Automation is the process of enabling a machine or assembly line to run self-reliantly, thus dropping the need for human work to carry out a task. Automation could involve technology from small automatic sensing devices, to sophisticated autonomous robots. Whether complex or simple, the logical programming commands and powerful machinery of automated operations can positively change entire facilities. Automated dispensing technology from GP Reeves, for example, has provided a plethora of automated systems with proven accuracy and reliability. Why should you consider automation for your own warehouse? Here are our reasons to make this innovative transition:

Growth

Due to the extensive advantages provided by automated technology, a business that adopts automation into their manufacturing processes will benefit from probable growth in business. With automation, businesses can capture benefits and achieve competitive advantage. Since automated systems supply performance benefits like increasing throughput, increasing product quality, and decreasing production downtime, businesses can more rapidly evolve. As your company grows, so can your people. Everyone hopes to grow and progress in their field, and automation allows employees to do so in new ways. The progression of technological development is not stopping anytime soon. The more advanced machinery and automated systems become, the more the need for people who understand how they work and can innovate, develop, and adapt them will grow. The need for technological skills will increase as more technology professionals are needed to help with cutting-edge machinery. Employees can be encouraged to enter new areas of a company involving the use of greater creativity and complex information processing. Opportunities to grow often correlate with strong levels of employee retention, allowing for a business that is stable and promising.

Productivity

Automated systems enable manufacturing facilities to have unprecedented production abilities. Through allowing humans to be more effective, acting for a longer extent, and taking care of tedious activities, automated technology can significantly heighten production capabilities. The use of automated machinery enables assembly to run 24/7 if desired. Because robots and automated systems do not require bathroom breaks, meals, or the occasional lunch break that turns into an accidental nap, they are able to run longer and further improve productivity. When managed with an automated system, assembly line processes have a longer production duration, increased stability, and manufacturing line sustainability. This allows for reliable and consistent levels of productivity and effectiveness throughout a production period. No more worrying about lost production time on company burrito day. Automated systems additionally free employees from having to complete tedious and time-consuming manual functions. Rather than spending work hours on routine, brainless tasks, employees can carry out more value-added tasks in other areas of the assembly line that supply greater benefit.

Reduced Lead Times

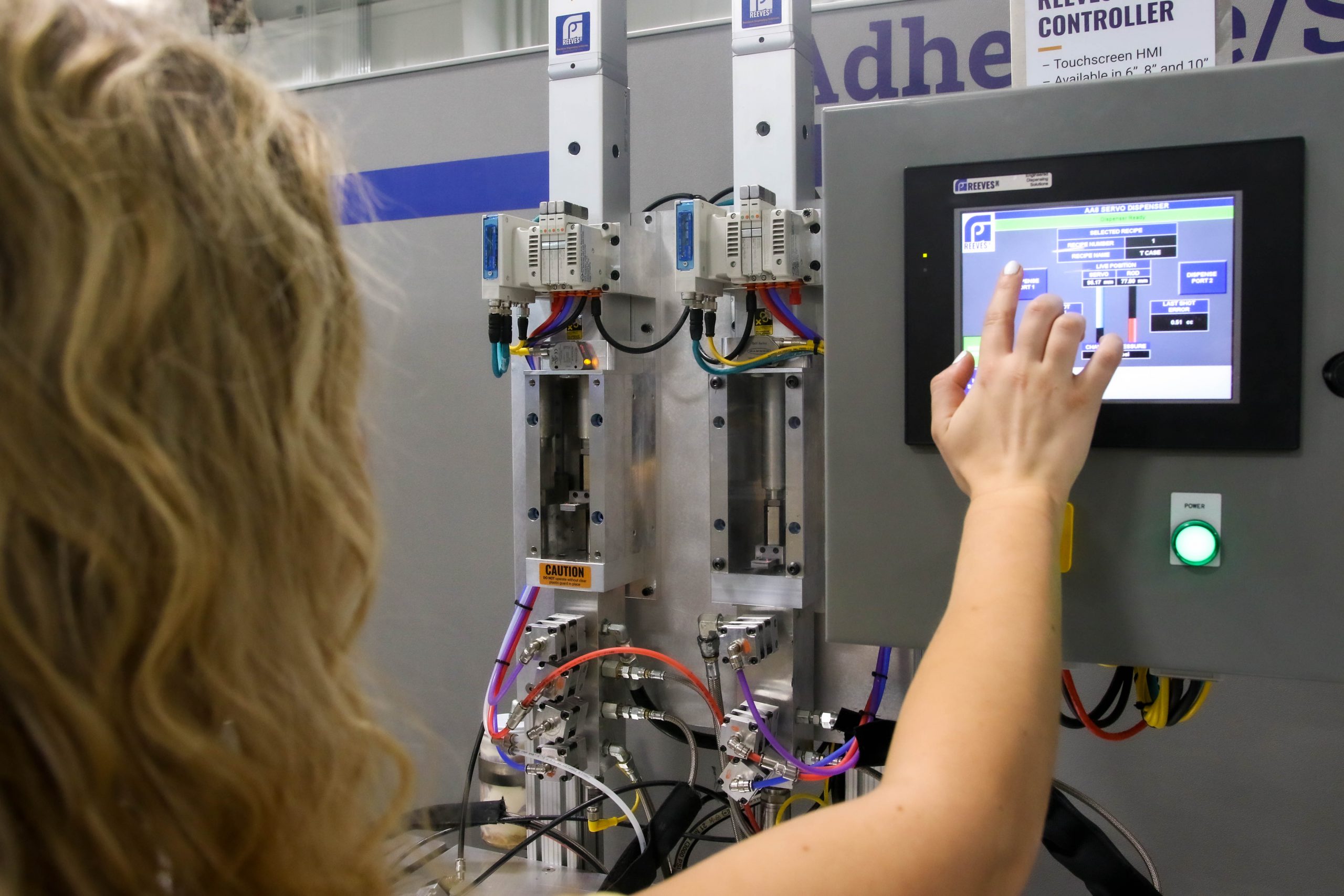

By using automation within a warehouse, an assembly procedure can become much more efficient and thus reduce product lead times. Automated systems supply an innovative resourcefulness to manufacturing lines so that products are ready for shipment faster than ever before. In addition, automated systems can cut latency and errors associated with manual operations. Because automated machinery provides repeatable accuracy, fixing human mistakes or making up for lost time will no longer be a concern of project managers. This type of production tactic can also allow for operational cohesion across all processes. With automation, standard products will all reach the same production standards and there will be no concern for wasteful discrepancies. This is modeled by the dispensing systems of GP Reeves, where our equipment provides an unprecedented level of repeatable accuracy to the exact specifications of our customers. Overall, automation can offer a level of efficiency that gets products on delivery trucks in a prompt fashion, while still supporting the utmost standards of product quality.

Eliminated Waste

Wasted time, energy, and labor are the enemies of manufacturing warehouses. With the help of automation, these dilemmas can be successfully circumvented. In terms of inventory management, automating manufacturing procedures like picking up parts or materials can reduce the amount of lost or misplaced materials and minimize the expiration of time-sensitive inventory. In terms of warehouse operations, even highly skilled employees cannot compete with the repeatable accuracy provided by automated systems. Some automated machines can even perform multiple operations at once, cutting any unnecessary time spent dealing with moving materials from one workstation to another. The automated systems from GP Reeves eliminate waste by distributing material with an immaculate level of accuracy. Unlike other material delivery methods like applying grease with a brush, equipment from GP Reeves distributes the exact volume of material necessary to adequately lubricate a device.

Enhanced Cost-Effectiveness

When a manufacturer chooses to implement automated technology into their production line, they will be able to complete simple processes in a more efficient manner and save on manufacturing expenses. This means less monetary capital is wasted on all the simple, repeatable tasks in a line, making up for the negative impacts of manual or mechanical labor. With automated technology, businesses spend less money on the assembly of products and more on better snacks for the break room.

Vitality

By automating your production lines, you are preparing for a manufacturing process that will maintain its reliability and durability well into the future. As long as equipment is properly supported, automated machines do not suffer the consequences of working long hours or the added stress of organizing the company’s Christmas party. The adoption of automated systems also helps your overall business to preserve lasting vigor and advancement. By using automated technology, a business can support assembly lines with automated systems while human employees can further develop and evolve products and business models. The shift to automation allows for added value to a company’s overall processes.

Safety Improvements

Warehouse jobs can be dangerous, and even some of the most compliant operations still maintain sporadic workplace injuries. When conducting manufacturing processes manually, there is always some inherent ergonomic risks. From serious damages like machinery accidents or falling freight to chronic conditions like stress or trauma injuries, assembly workplaces put workers at risk. To combat this risk, it may be helpful to use automation, which simplifies assembly lines and can ensure compliance with safety regulations occurs in every step of a process. Automated machinery technology has also advanced in a way that allows it to check and detect any potential malfunctions before they cause harm. Overall, to increase the wellbeing of your warehouse employees, one must consider the multitude of safety related benefits provided by automated systems.

There are a multitude of benefits associated with a manufacturer’s transition to working with automation technology. As the world of production and assembly continues to evolve, automated systems will continue to encourage growth and expansion within a vast array of mechanical industries. The team at GP Reeves is enthused to utilize its automation knowledge and the several partnerships we have with other automation experts to propel the evolution of facilities with our thoughtfully engineered automated dispensed systems.

Interested in an Automated Dispensing Application?

Fill out the form below and we’ll follow up with you!